ID plates can be found on equipment in both residential and commercial settings, and they are often made of metal. Here are five reasons metal is the material of choice in these applications.

- Durability - ID plates need to be able to stand up to a variety of harsh environments. Metal satisfies this requirement, with both aluminum and stainless steel as durable solutions. ID plates made from aluminum or stainless steel are expected to last for the life of the equipment that it is applied to.

- Sustainability - Industrial equipment is not typically designed to be used once and thrown away. Metal is a recyclable material, making for responsible production of equipment. Up to 75% of all aluminum is recycled today. In the same manner, stainless steel products are typically made from 60% recycled material.

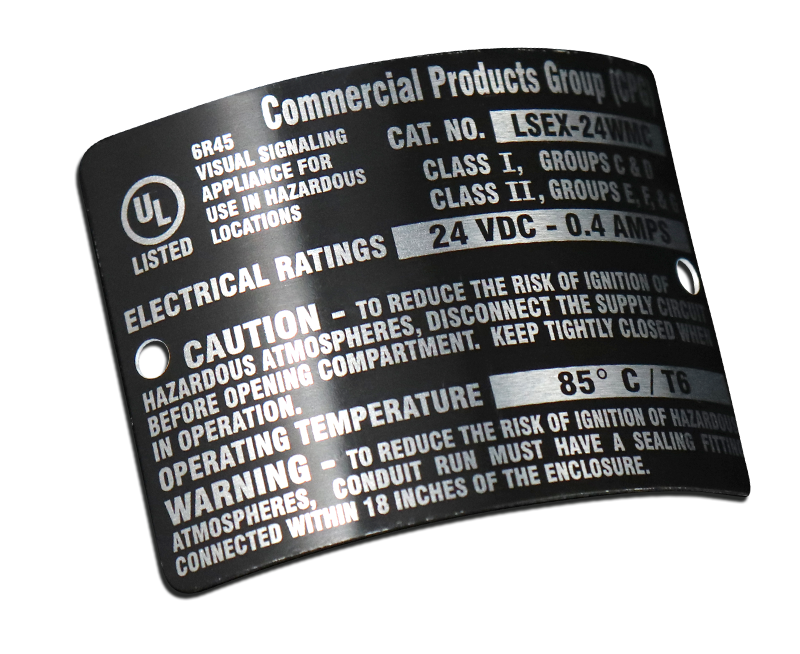

- Compliance - The information shown on equipment tags provides critical safe operating and maintenance details. Many of these are in line with regulations and specifications put out by governing agencies.

- Longevity - Equipment tags and ID plates need to last. Industrial equipment can be subjected to harsh environments including extreme heat or cold, exposure to chemicals and grease, as well as heavy handling. Metal is robust and stands up to these applications without deterioration of the nameplate or tag.

- Customization - The ability to use standard size and shape tags means uniformity across equipment. Rather than simply ordering from a catalog, printing on metal means custom decoration so that the equipment-specific information, company details, or any other text or graphic is designed to suit your needs. You supply the artwork and direction, and we translate it onto the surface of the metal.

How Can We Help?

Choosing the right material for ID plates minimizes the risk of critical information being illegible or the data plate wearing away. We have a team of experienced professionals ready to work with you to identify the right material and processing for equipment tags that last.