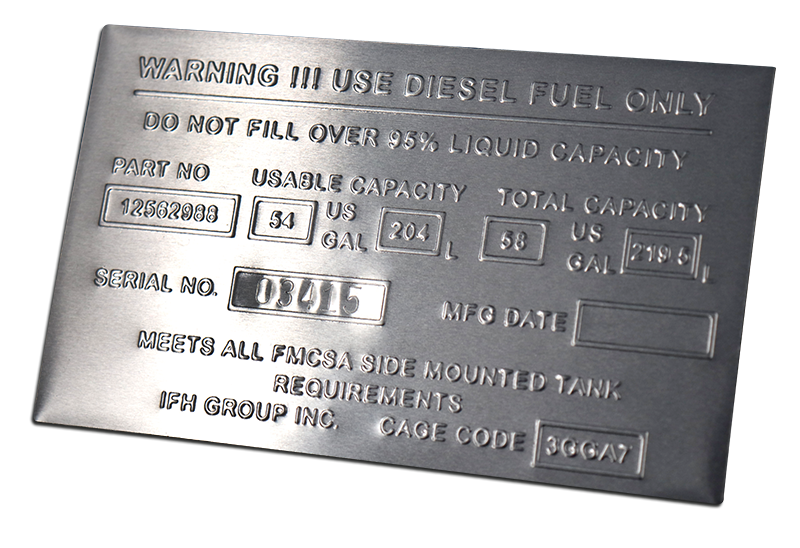

OSHA, NFPA, and other regulatory bodies set strict regulations for the type of information that can be displayed on industrial ID plates. While there are several options to choose from, embossing is a great choice to make this critical information legible, durably marked, and plainly visible after the equipment is installed.

What is Embossing?

Embossing is a custom tooling process where a metal die creates a three-dimensional image. The die squeezes and pushes the metal up from the surface, which raises and textures the metal graphics. The reverse of this is called debossing, where the metal is pushed down for indented text and graphics. The height and depth of the embossing depends on the thickness of the material and the type of tool that is used. Aluminum, brass, and stainless steel are metals that can all be embossed.

Standard tolerances for embossing are pre-determined. Outlined here are established tolerances based on .020” thick aluminum. Other options in material type, thickness and emboss height are available.

|

Emboss Type |

Tolerance for .020" Aluminum |

|

Height |

Maximum height = .015" |

|

Logo or Text |

Minimum stroke or line width = .015" Space between embossed characters = .030" |

|

Border |

Minimum stroke or line width = .015" Space to edge of part = .030" |

|

Background |

Edge of part must return to original height Minimum lip/space to edge of part = .030" |

Reasons to Emboss Metal ID Plates

Embossing is an option for dimension and permanent graphics. The raised areas withstand damaging environments, which ensures that any essential information can be displayed after years of use.

Physical Dimension - An emboss tool adds a layer of dimension to push the surface of the metal up. This results in raised graphics, text, borders, etc.

Durability and Longevity - The embossed area is a permanent marking that will stay in place for the life of the product. It is a design element that cannot be erased or scratched away. UV curable inks and UV clear coat provides protection against exposure to the elements and harsh environments.

How Can We Help?

No matter if you are well seasoned in ID plate design or need some guidance, we can help. Our skilled Customer Care and Art departments will work with you to understand if embossing makes sense for your critical information.