When creating a nameplate or product identification tag, choosing the right adhesive is one of the most important decisions you'll make; and it takes on another level of importance when the adhesives are going to be exposed to the elements, (because, let's be honest, it doesn't matter what your nameplate or data plate says if it's laying upside down on the ground...). One of the most common choices that people make is choosing a pressure sensitive adhesive to ensure a strong bond between your nameplate and your product or machinery. In this blog, we'll walk through the things you should keep in mind for adhesive exposed to the elements.

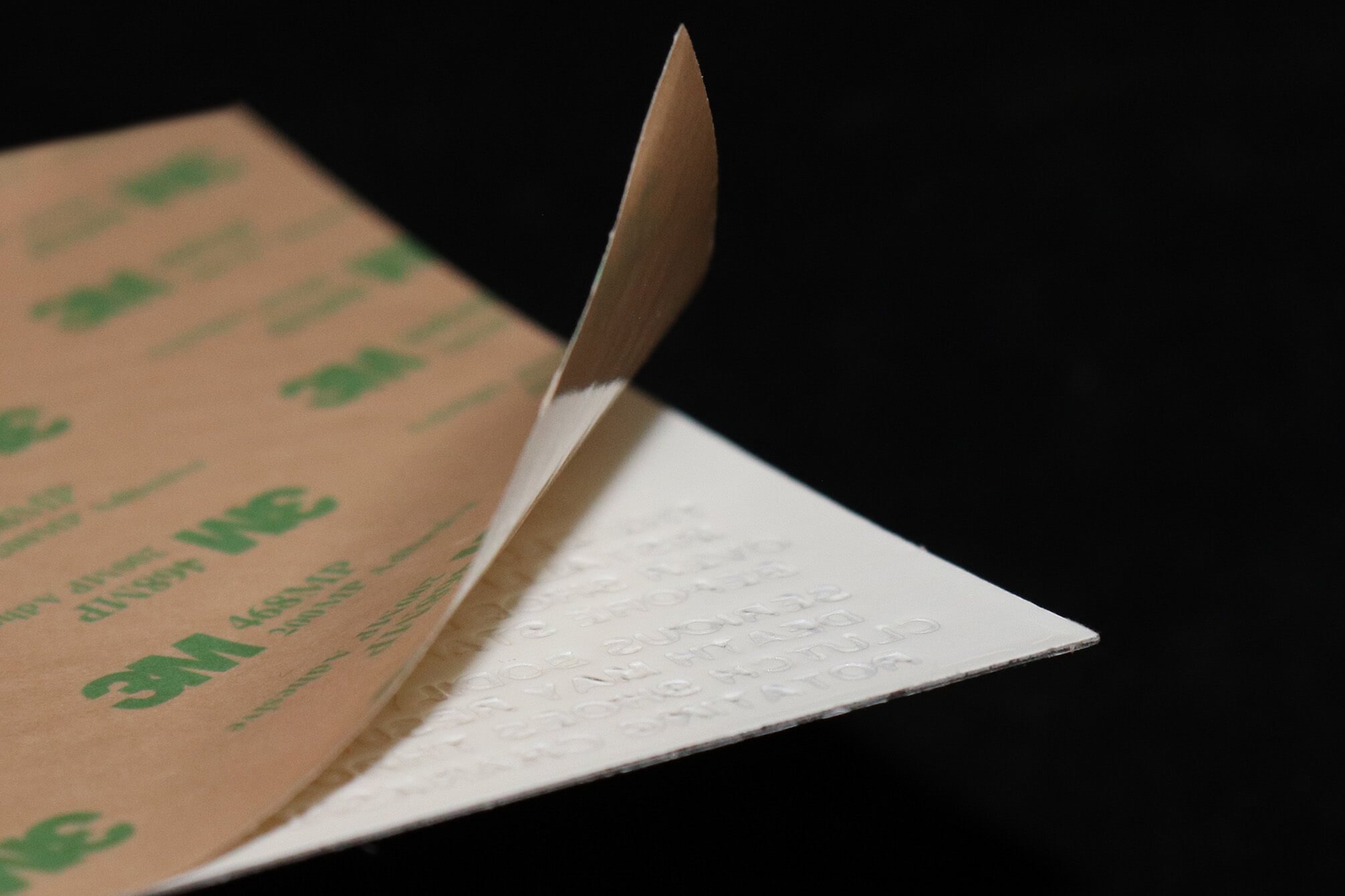

Just for some clarity, pressure sensitive adhesive is an adhesive that we use on nameplates, labels, data plates, and decals that ensures a quick and secure bond when pressure is applied. We have a variety of pressure sensitive adhesives available, depending on your substrate and the intended use.

Environmental Challenges for Adhesives on ID Plates

Outdoor equipment and machinery, like farm or construction equipment, face a barrage of environmental challenges - like sunlight, UV rays, humidity, and extreme temperatures. These elements pose a significant threat to the adhesion and bond of nameplates or labels. Because of this, it's really important to look past the standard adhesives and evaluate if another adhesive could stand up better in these conditions.

Things to Consider when Choosing a Nameplate Adhesive

Understanding the surface your nameplate will adhere to is important to keep in mind. Some adhesives are known for sticking well to flat metal or plastic surfaces, but outdoor equipment often is coated in paint or a powder-coating. Meaning the adhesion wouldn't be as strong as if it were on a plain metal surface. Additionally, plastic surfaces could present a challenge because of their texture or low surface energy. To make the best choice, consider the substrate type, texture, curvature, and surface energy of the mating surface.

Badge or Label Application Method

How will the safety label be applied? This will influence the type of adhesive required for a secure attachment.

Storage Requirements

Consider the storage conditions for your equipment and how they may impact the adhesive's performance over time. Will it be kept indoors, or will it be 24/7 out in the elements?

Bond Specifications

Identify the specific requirements for the bond. Different applications may require varying levels of adhesive strength. Will you ever need to remove and place elsewhere?

Ensure Adhesion in the Most Extreme Environments

In scenarios where extreme outdoor exposure is likely, a combination of pressure sensitive adhesive with mechanical fasteners like rivets or screws can provide that extra security. This approach provides a strong attachment, making it extremely challenging for the nameplate to be removed.

How can we help?

Understanding the conditions that your exterior badge will face ensures we use the right decorating processes, topcoats, and adhesives. Reach out to our Customer Care team to help you figure out a durable and effective solution that will stand up in even the harshest environments.