Electronic devices and commercial equipment sometimes have intricate pieces and components which need shielding, or protection against vibration and moving parts. Die cut gaskets, seals, and insulators are effective solutions for these applications.

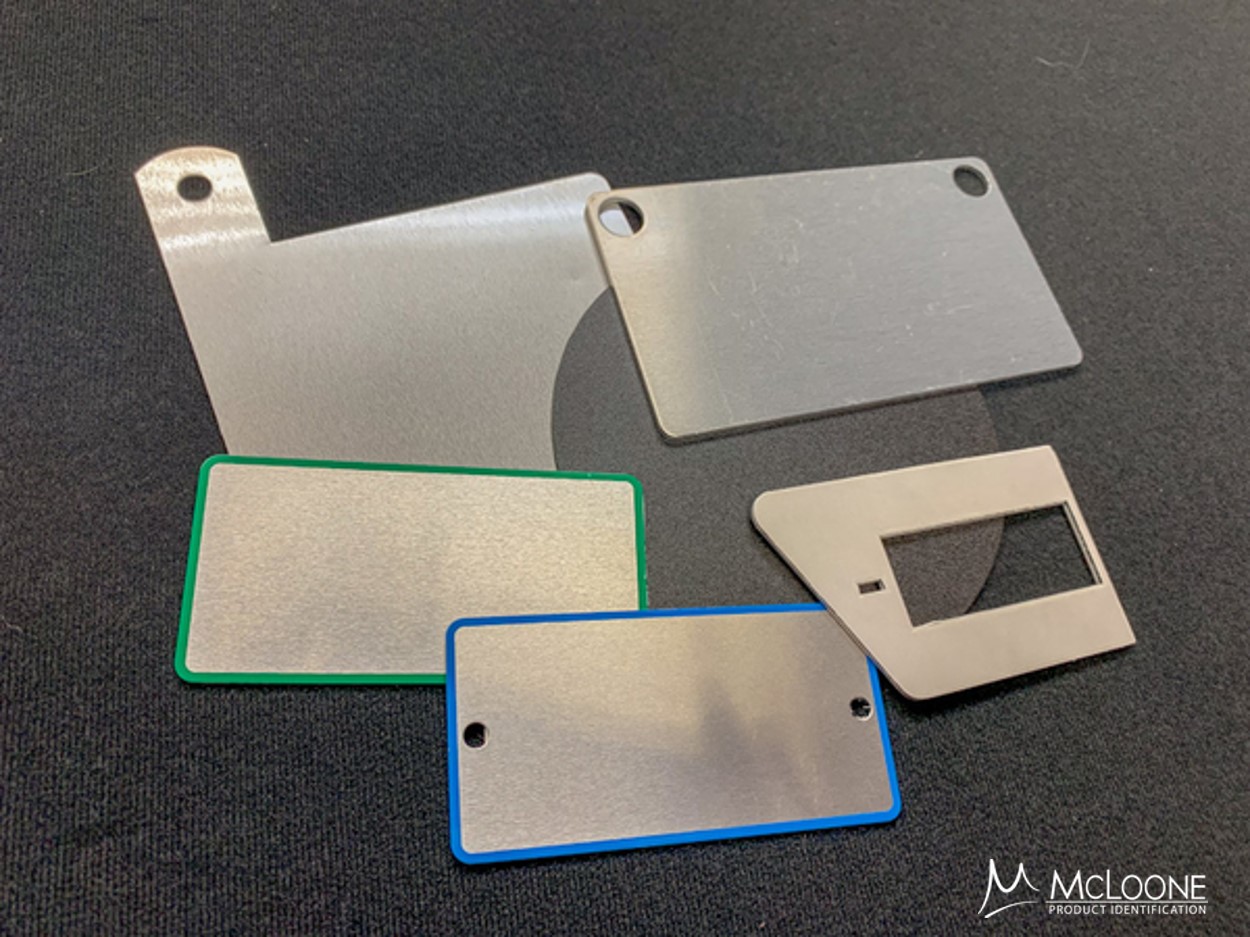

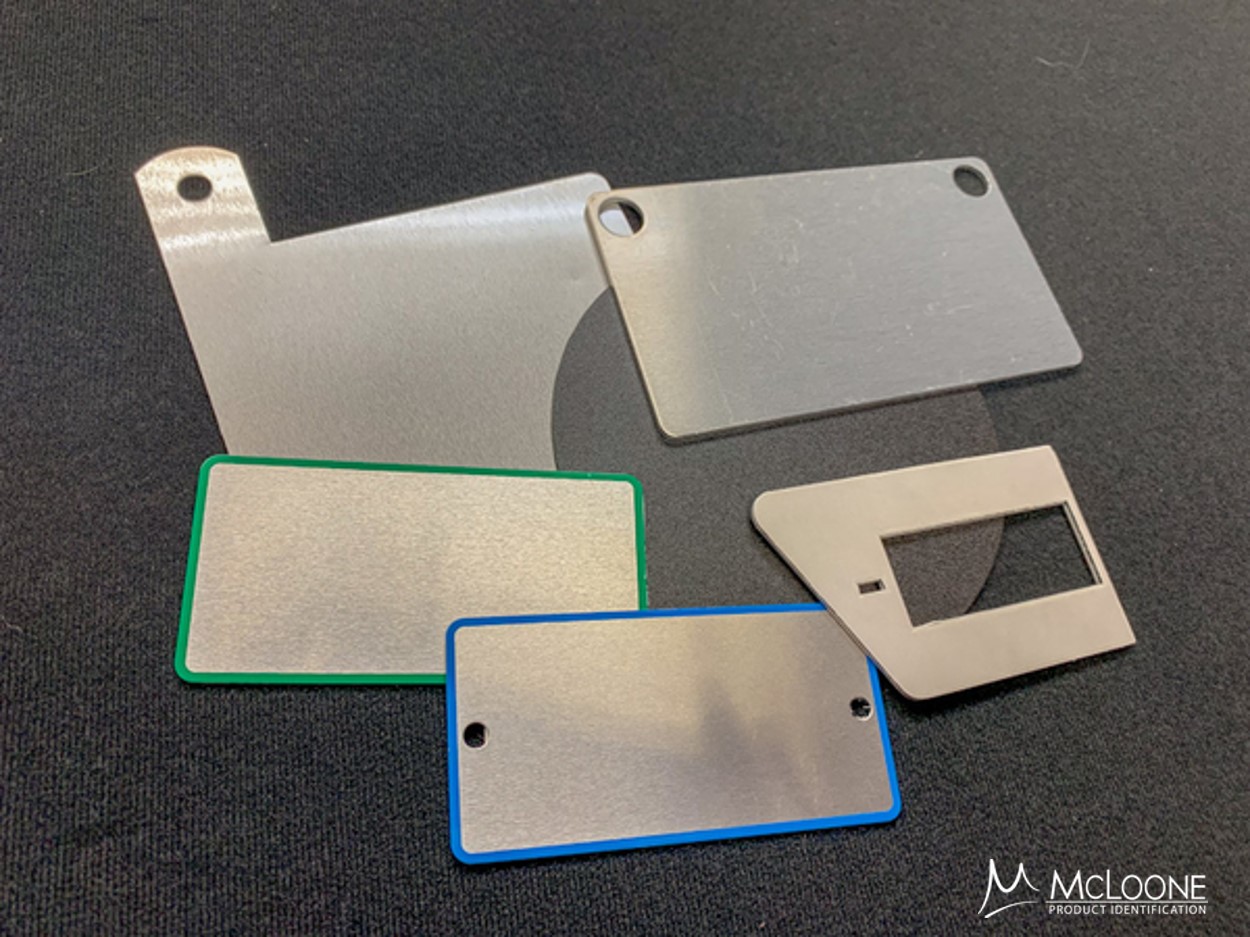

McLoone has capabilities to fabricate metal, foam adhesive and polycarbonate spacers. These type of products can be cut into any shape and configured with custom piercers or hole punches to allow secure attachment. They solve specific concerns including sound dampening, EMI/RFI shielding, insulation from heat or cold, and filling a space or gap between mating surfaces.

Gasket and Seal Solutions

Gasket and seals are typically non-decorated components that are hidden from view on the product. They serve as solutions to:

-

Prevent leakage

-

Reduce vibration

-

Protect against shock, dust, or moisture

Spacers and Gap Filling Solutions

Secure attachment of an overlay, panel, or serial plate can be difficult when there is an uneven surface, or there is a bend to the part. Die cut spacers made from foam adhesive help resolve this issue. Spacers are used to:

-

Even out a rough surface

-

Insulate against heat or cold temperatures

-

Fill a gap between mating surfaces

Decoration or Not?

Typically die-cut components are ordered and supplied without decoration - simply cut from appropriate material, to the size and shape needed. Options for customization for colored borders or adding some instructional text can be reviewed so that the result is a truly unique solution that fits the application and assembly needs of the product.

How Can We Help?

A library with thousands of dies means viable options for your die-cut component needs. In-house tooling means quick turnaround for custom builds. We will work with you to identify the best material and configuration to solve common concerns for filling a gap, shielding from leaks and moisture, or lessening vibration.

Related Posts

Adhesive Solution for Rough Surfaces

Graphic Overlays Explained

Tooling Options for Nameplates and Labels