When designing product identification and overlays, conversation on adding impact or drawing attention to a logo can come into play. Embossing is one of the ways to add dimension to nameplates and labels. It does impact cost, and for that reason, it can be a reason to question whether it is worth it. This post reviews some reasons embossing is needed in order to help you determine if it is the right solution for your needs.

What is Embossing?

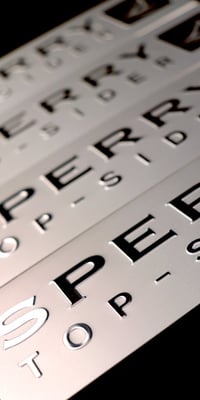

Embossing is a custom operation in the production of nameplates and labels that raises up the surface of either the metal or plastic material. The crispness or height of the emboss is dependent on the type and thickness of the material.

Why Emboss Metal Nameplates

Why Emboss Metal Nameplates

One of the most common reasons to emboss metal nameplates is simply for the dimension that the operation creates. Graphics, text, borders, patterns, etc are all possibilities for embossing on metal.

Embossing also is a permanent way of marking a nameplate. In exterior or industrial applications, this can mean the difference in communicating critical safety information.

An embossed logo naturally stands out. The raised area can be left bright with a contrasting low gloss background for a two-tone look that increases perceived value for the brand. It is an enhancement that shows more detail than a basic flat nameplate.

Why Emboss Plastic Labels or Overlays

Why Emboss Plastic Labels or Overlays

Embossing on plastic is typically a functional solution. Embossed buttons or borders on overlays clearly show product users the specific areas to push for on/off or other operations.

Just like on metal, embossing on plastic can be used to grab attention. A logo or text become the focus of the label.

Background patterns on plastic can be embossed for added interest and another design element to take the label from an average sticker to an impressive showcase for your brand.

Is Embossing Worth it?

There are instances when embossing is non-value-added. This is most common when doming is applied to a nameplate or label. The resin material of the dome fills in the dimension created by the emboss, which makes it difficult to see. On metal nameplates, embossing with doming can be detected if there is good contrast between the embossed graphics and background.

In the end, the look of your metal nameplate or plastic label is up to you. It is a custom tool operation that will impact the cost of your nameplate or label. Take a look at why you are considering embossing. Embossing is a durable solution for nameplates, labels and overlays that are needing to make an impact, reinforce the price point of your product, or when there is functional reason for the emboss.

How Can We Help?

Creating custom solutions for product identification has been our focus for over 65 years. Brands from every industry have trusted us to produce quality nameplates and labels that work with their individual strategies. Need ideas to take your brand to the next level? We can help!

Related Posts

Embossed Metal Nameplates Explained

Where and When it Makes Sense to Emboss Metal Nameplates

When and Where Embossing Plastic Labels and Overlays Makes Sense

eBook: Heavy Duty Plastic Labels with Dimension through Embossing