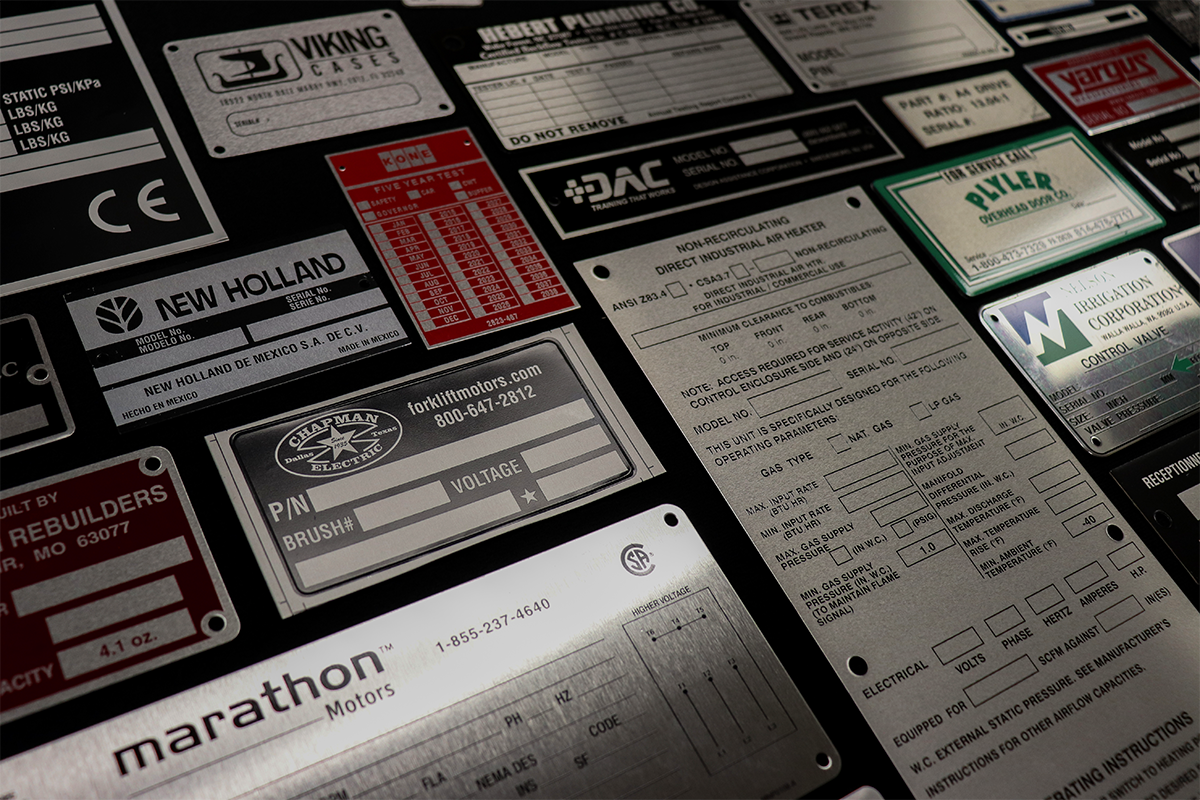

Product identification plays a critical role in how products and equipment are used, maintained and perceived. From data plates and ID plates to nameplates, emblems, and decals, these components communicate essential information - everything from operating instructions and safety warnings to branding and inventory.

Because product identification is designed for durability, it can sometimes be overlooked. But over time, environmental exposure, general wear and tear, and changing requirements and regulations can reduce their effectiveness. If your nameplates or ID plates are no longer performing as you intended or are just not up to your standards anymore, it may be time to upgrade. Here are 5 signs it isn't doing its job:

The Information on Your Nameplate is Fading or Difficult to Read:

This might seem obvious to some, but it is often overlooked by many. Clear, legible information is the foundation of an effective piece of product identification. If text, safety symbols, or maintenance information are fading due to UV exposure, abrasion, or contact with chemicals, it cannot effectively do it job.

Decals or data plates in this condition don't just look worn down, they create safety and compliance risks, disrupted maintenance schedules, and general usage confusion. Durable substrates and printing methods, as well as protective finishes, help ensure the information remains legible for the life of the product.

If you're looking for more information on durable product identification, download our free ebook: Premium Outdoor Metal Nameplates

Questions about what symbols, text, or warnings should be on your product identification, or if it's up to current standards? Click here.

The Emblem or Data Plate is Damaged or Failing in its Environment:

Peeling, warping, corrosion, and cracking are all signs that your product identification isn’t suited for the environment it’s in.

Your ID plates or emblems need to be engineered to match the demands of the environment it will be used in, whether that’s outdoors, in high-heat, or frequently around chemicals. Upgrading to a more durable substrate can significantly extend their lifespan and reduce early failure.

Looking for more information on Product Identification? Read our blog, Sun, Rain, Clean, Repeat: Product Identification that Lasts

Need information on attachment methods? Click here to read our free ebook: Nameplates with Staying Power

Your Equipment, Product, or Requirements have Changed:

Products, rules, and regulations change all the time. Updates to operating instructions, changes to safety standards, or new certifications can quickly make existing product identification outdated.

This is especially common for OEMs that refine product or equipment design or roll out new models over time. Reviewing your nameplates or ID plates frequently can help ensure your information remains accurate, consistent, and compliant.

Click here for a blog on Leveraging Visual Communication to Share Critical Information

Branding on Your Nameplate is Inconsistent or has been Updated:

A nameplate is the most permanent representation of your brand on your product or equipment. If your logo, colors, or graphics are inconsistent or no longer fit within your current brand guidelines, it’s time for a refresh!

Update your product identification with custom color matching and shapes, an embossed logo, and dimensional elements like a pattern or texture. All options that stick to your brand standards while maintaining the highest level of durability and quality.

Read our blog: Your One-Stop-Shop for Product Identification

Want to include a pattern or texture? Click here!

Replacing Your Emblem or Data Plate has Become Routine:

When replacing emblems or decals has become part of your routine, it’s an obvious sign that it wasn’t built for the long term.

These frequent replacements increase costs, downtime, and frustration. Taking the time to design a product identification solution now, will reduce costs overtime by minimizing failures and extending legibility.

Are you replacing your product identification because of attachment failure? Click here.

Taking a Proactive Approach to Product Identification

A nameplate or data plate may be a small part of your overall product or equipment, but they have a significant impact. A regular evaluation of how your ID plates, decals, and emblems are performing can improve safety, support compliance, and reinforce brand recall.

By choosing the right substrates, finishes, and printing processes, your product identification can be designed to last as long as the product or equipment it’s attached to!

Click here to read: 5 Tips to Maximize the Lifespan of Your Nameplates and Labels