Placing an order for your nameplate or label needs at the very least the part number, quantity, and delivery date information. Have you thought about how these parts are packed? Here are some of the standard fulfillment options offered for metal nameplates and plastic labels.

Snug and Tight Packing of Nameplates and Labels

Many orders are able to be securely packed simply by placing parts snug and tight into a box. Specific quantity bundles can be counted and grouped so that your receiving and assembly processes are streamlined. When appropriate, paper liners may be used between parts as additional protection from scratches during shipment.

Many orders are able to be securely packed simply by placing parts snug and tight into a box. Specific quantity bundles can be counted and grouped so that your receiving and assembly processes are streamlined. When appropriate, paper liners may be used between parts as additional protection from scratches during shipment.

This option works for both metal and plastic material and is one of the most common and cost efficient solutions to fill an order. Parts with or without adhesive can be packed in this manner.

Cell Packing for Metal Nameplates

Metal parts that are formed or fabricated with mounting tabs may be better suited to be packed in separate sections so that each individual part sits by itself. These sections are referred to as cells. The benefit of this type of packing is that the parts do not touch each other so there is decreased risk of scratches.

Metal parts that are formed or fabricated with mounting tabs may be better suited to be packed in separate sections so that each individual part sits by itself. These sections are referred to as cells. The benefit of this type of packing is that the parts do not touch each other so there is decreased risk of scratches.

Special packaging material is required for this option and can be a cost driver. It does provide consistency in box count and weight. Parts with or without adhesive can be packed in this manner. Cell pack is not generally a solution for plastic parts.

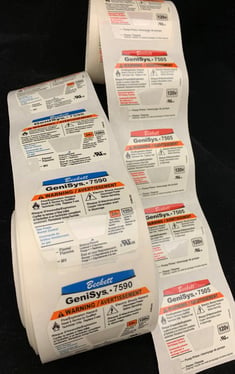

Roll Labels for Easy Assembly

Flexible material like polyester, polycarbonate and vinyl are used to create labels and overlays. Because of the material's makeup and being able to bend without tearing, these labels can be reviewed for supply in rolls. This can be cost effective for large quantities of labels. This type of packing option means efficient assembly as well.

Flexible material like polyester, polycarbonate and vinyl are used to create labels and overlays. Because of the material's makeup and being able to bend without tearing, these labels can be reviewed for supply in rolls. This can be cost effective for large quantities of labels. This type of packing option means efficient assembly as well.

To review for roll labels, it is important to specify size of the roll, whether the labels should release from top or bottom of the roll, and if there is a specific quantity of labels per roll. These are custom requirements for the label and may be subject to special pricing. Roll labels are not an option for metal parts or labels with doming.

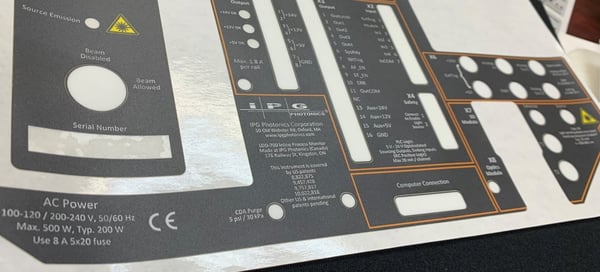

Nameplates and Labels Supplied in Strips

Another common way to supply nameplates and labels is in strip form. This means that metal nameplates or plastic labels are laid out in a specific quantity and then packed with multiple parts on a strip. These types of labels have pressure sensitive adhesive.

Another common way to supply nameplates and labels is in strip form. This means that metal nameplates or plastic labels are laid out in a specific quantity and then packed with multiple parts on a strip. These types of labels have pressure sensitive adhesive.

This is an efficient way to pack parts that are sequentially numbered, have variable data like bar codes, or that are domed. Assembly of these types of labels means just pulling away the liner and sticking to the mating surface.

Family Parts in Kits

Plastic labels supplied in a kit format makes for an efficient and streamlined assembly process. All the information labels can be supplied in a strip or on a single card so that your build of materials need to simply call out one label item. The labels can be provided so that they are kiss cut for easy peel and stick procedure. This packing solution is cost efficient because multiple labels are produced within one order. Warning labels that require printing in multiple languages are one example of how this type of order filling works. Kitted parts are not generally viable for metal nameplates.

How Can We Help?

Now that you've reviewed some common order fill options for metal nameplates and plastic labels, you should feel confident that your order is safe with us. Still have questions? Send us a note and let's get your concerns put to rest.

Related Posts

Packaging Options for Safe Transit for Nameplates and Labels

Durable Labels Supplied in Kits Minimize Cost

3 Considerations for the Design of Nameplates and Labels

3 Things to Expect from a Nameplate Project